Machine Reconditioning

Reconditioned WEBB Equipment

Machine reconditioning significantly extends the lifespan of equipment, maximizing your return on investment (ROI). This process enables businesses to enjoy improved performance and reliability at a lower cost compared to buying new machinery. Moreover, reconditioning reduces operational downtime, enhancing overall efficiency and productivity. It also promotes environmental sustainability by minimizing waste, making it an excellent choice for organizations focused on both performance and sustainability.

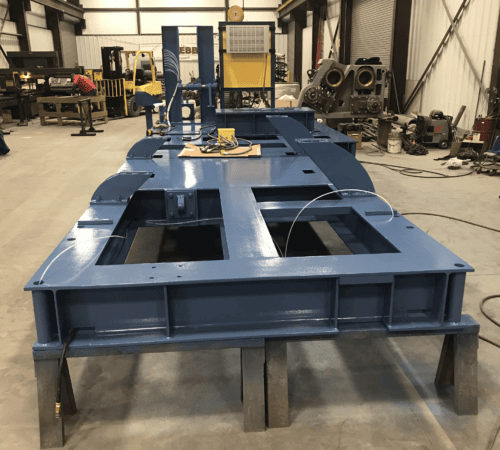

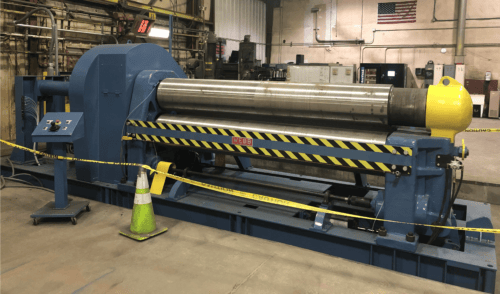

Every machine that comes into the WEBB Corporation’s plant to be reconditioned undergoes a thorough evaluation to identify any wear and tear, functional issues, or parts that require repair or replacement. Extensive cleaning is completed to remove debris, dirt, and grime, allowing for a clear view of the equipment’s condition. Damaged or worn components are replaced with high-quality machined parts that meet or exceed original specifications. Skilled technicians and machinists conduct all repairs to restore equipment to its optimal state. In some cases, equipment may be retrofitted with updated technology and features to improve performance and efficiency, ensuring that it meets current industry standards.

Every machine that comes into the WEBB Corporation’s plant to be reconditioned undergoes a thorough evaluation to identify any wear and tear, functional issues, or parts that require repair or replacement. Extensive cleaning is completed to remove debris, dirt, and grime, allowing for a clear view of the equipment’s condition. Damaged or worn components are replaced with high-quality machined parts that meet or exceed original specifications. Skilled technicians and machinists conduct all repairs to restore equipment to its optimal state. In some cases, equipment may be retrofitted with updated technology and features to improve performance and efficiency, ensuring that it meets current industry standards.

Many of our customers have successfully benefited from having their WEBB machines reconditioned. Each unit is meticulously restored to its original working condition, and thanks to the use of modern alloys, many of these machines leave our factory with even greater durability than when they were first built. This ensures you have a secure and reliable investment.

If you’re interested in having our service team recondition your WEBB equipment or in purchasing a reconditioned machine, please call the number below or reach out to us through our contact form.