Tank Assembly Press

AP Series Tank Assembly Press

- Up to 37 Tons of Closing Pressure

- Built-In Fit-Up Rolls

- Built-In Kick-Out Lift

- Adjustable for Tank Diameter

- Adjustable for Tank Length

- Four Standard Sizes

- Customizable

The Webb Corporation’s Tank Assembly Press is specifically designed for assembling tanks and vessels, making it an invaluable asset for industries that manufacture these products. It is especially beneficial for those who use the off-set forming process, as well as those using conventional back-up bars, when joining tank shells together and or end-caps to tank shells that require substantial pressure when assembling. With a powerful hydraulic closing pressure of up to 37 tons, our AP Series press allows for more precise assembly preparation, resulting in high-quality and faster welding of tank and vessel joints. With its robust design and easy-to use features, the Webb Corporation’s Tank Assembly Press is a top choice for improving workflows and product quality in tank and vessel manufacturing. Scroll down to the bottom of the page to view the specifications of the standard AP Series models available.

Description:

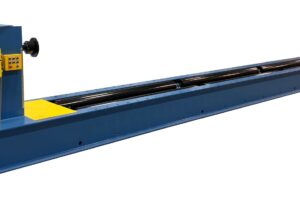

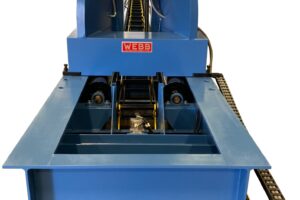

Heavy fabricated steel construction is used throughout The Webb Corporation’s AP Series , with massive “I” beams forming their main bases. The kick-out conveyor is hydraulically operated and has built-in rollers for horizontal movement of tank shells. Steel pipe fit-up rollers, which are built into the base and mounted on anti-friction bearings, are designed to assist in the alignment and movement of the tank shells during the fabrication process. These rollers are idler-type and built in multiple sections, with a separation between the sections to allow for two-course vessels. The standard spacing of the sections is for two-course propane (LPG) vessels, but they can be placed according to customer requirements upon request. All controls are mounted on the headstock unless otherwise specified. Pressure is applied through ball and socket swivel joints to head cups, which reduces the tendency of the tank to move upward out of the press when pressure is applied. Swivel joint ram plates are provided with a mounting hole for head cups, but HEAD CUPS ARE NOT SUPPLIED WITH A MACHINE. The machines listed are our standard models, but we are able to customize any of the features to meet your needs.

| Model Number | AP-48 | AP-60 | AP-72 | AP-84 |

|---|---|---|---|---|

| Max. Working Diameter | 48" | 60" | 72" | 84" |

| Min Working Diameter | 24" | 24" | 24" | 24" |

| Max. Working Length | 18' | 24' | 30' | 32' |

| Closing Pressure | 25 Tons | 30 Tons | 37 Tons | 37 Tons |

| Overall Length | 28' | 32' | 44' | 44' |

| Overall Width | 4' | 4' | 4'-6" | 4'-6" |

| Overall Height | 6'-6" | 8' | 6' | 6'-6" |

| Hydraulic System Motor | 5 HP | 5 HP | 5 HP | 5 HP |

| Adjusting Motors | 1/2 HP | 1/2 HP | 1 HP | 1 HP |

| Approx. Shipping Weight | 10,000 LBS. | 14,000 LBS | 18,000 LBS | 20,000 LBS |